Categories

- - Deep Well Submersible Pump

- - End Suction cenfrigual Pump

- - End Suction Close cenfrigual Coupled Pump

- - Fire Pump

- - Gear Pump

- - Horizontal Multistage Pump

- - Horizontal Split Casing Pump

- - Motors

- - Pressure Booster Pump

- - Submersible Pump

- - Valves & others

- - Vertical in-line Pump

- - Vertical Multistage Pump

- - Vertical submersible Pump

- - Vertical Turbine Pump

Author Archives: safeway

DRAKOS Specification:

- Widley applied in general machinery and industries such as pumps & water treatment , fire flighting system, road machinery, petroleum,chemical,metallurgy, cement and paper milling

- IP55 Protection, Class F Insulation, B Temperature Rise, S1 Duty, Service Factor 1.15

- Rated Voltage:415V

- Rated Frequency: 50Hz

- Ambient Temperature: 50*c

- Altitude:<1000m

- Cooling Method:IC411

Working Conditions

- Medium: Water

- Temperature: 0 ~ 70º C

- Pressure: PN 10, PN 16, PN 25

Technical Specifications

- Design Standard: EN 1074-5

- Test Standard: EN 12266-1 (ISO 5208)

- Face to Face Dimension: EN558-1 Series 1

- Drilling Flange: EN 1092-2 (ISO 7005-2)

- Protection: Fusion Bonded Epoxy Coated

Applications

- Water Plant

- Pipeline

- Building

Features

This pump is a horizontal and split type, with both pump casing and cover split at the central line of the shaft, both water inlet and outlet and the pump casing cast integrally. A wearable ring set in between the impeller and the pump casing, the impeller axially fixed upon an elastic baffle ring and the mechanical seal directly mounted on the shaft and without a muff. These will greatly reduce the works of repair for the pump user. The shaft is made of stainless steel the packing seal structure is set with a muff to prevent the shaft from worn out. The bearings are open ball bearing type and a round post roller bearing and axially fixed upon a baffle ring. There is no thread and nut on the shaft so the moving direction of the pump can be changed any time without the need to replace the shaft. The impeller is made of Bronze material.

Operating Data

Pump Size DN : 80 ~ 250 mm

Capacity Q : ≤ 345 L/sec

Pressure P : ≤ 3 Mpa

Working Temperature T : up to 80º C

Medium : Pure water and similar to that of pure water

Technical Data

- Size: DN50 (2”) to DN350 (14”)

- Nominal Pressure: PN10 /PN16

- Working Temperature: -45º C to +200º C

- Suitable Mediums: Fresh Water, Sewage, Sea Water, Air,

Oils, Alkalis, Salts, etc.

Standard

- Design & Manufacture According to

API 609, MSS SP-67, BS5155, BS EN593.

- Face to Face According to

DIN3202, API 609, MSS SP-67, BS5155, BS EN558, ISO5752.

- Top Flange According to

ISO5211.

- Pressure Test According to

API 598, BS EN12266-1, DIN3230, BS5155.

- Side Flange According to

DIN2501, ANSI125/150, AS129, BS4504, BS10D & E, JIS 10K.

Introduction

SLZA Series pumps are horizontal , axial suction, single stage, single suction centrifugal pumps. The design is in

according with 10th version of ANSI/API 610-2004 (Industrial centrifugal pumps for petroleum, heavy chemical

and natural gas). Among these series of pumps, SLZA is OH1 type and SLZA E/F is OH2 type. These pumps are

suitable for transferring liquid like clean fluid, low or high temperature flammable, explosive and corrosive liquid

with solid.

Performance Parameters

■ Aperture (DN): 25 ~ 400mm

■ Capacity (Q): 2 ~ 2400 m³/h

■ Head (H): up to 300m

■ Working Pressure (P): 2.5 MPa ~ 7.5 MPa

■ Working Temperature (T): - 80º C ~ 430º C

Applications

■ Refinery plant, petro-chemical industry, coal-process industry and low temperature projects

■ Chemical industry, paper-making, pulp and sugar refinery and normal process industries.

■ Water supply plant, Desalination

■ Heat supply and Aircondition system

■ Power plant

■ Environment engineering

■ Naval architecture and ocean engineering

Specifications:

1. 2 ways normally closed

2. SS304 or Brass Body

3. Piston Pilot Operated type

4. Working Temperature: PTFE: -20º C ~ 200º C

VITON: -10º C ~ 120º C

5. Pressure; 0.05 ~ 1.60 MPa

6. Voltage of AC or DC is available when required

7. IP65 coil, Class F

8. Medium: Steam, Hot water, Oil, etc.

Applications:

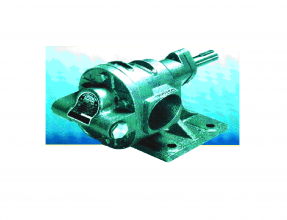

An Efficient, economical and reliable pump. It is suitable for pumping and transfer of all viscous liquids, oils and petroleum products.

An Efficient, economical and reliable pump. It is suitable for pumping and transfer of all viscous liquids, oils and petroleum products.

Technical Data:

- Single helical gears

- Hardened & ground shafts

- Maximum capacity: 50 LPM

- Maximum pressure: 10 kg/cm²

- Maximum temperature: 80º C

- Modified version for high temperature up to 250º C

- Modified version for molasses and vacuum application